Moss 2012-12-31 Pressure vessels are closed containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Thickness Calculation Of Pressure Vessel Shell - Free download as Excel Spreadsheet xls PDF File pdf Text File txt or read online for free.

Xls Pressure Vessel Calculations Asme Section Viii Division I Basincli Kap Tasarim Hesaplamalari Ahmet Oven Academia Edu

SHELL DESIGN THICKNESS CALCULATION BOTTOM PLATE ANNULAR BOTTOM PLATE DESIGN INTERMEDIATE WIND GIRDER DESIGN WIND DESIGN ANCHOR BOLT CALCULATION.

. 5 HT H - HD face load 23191 - 20425 2766. Manual Valves K. External pressure can be caused in pressure vessels by a variety of conditions and circumstances.

T u 15 m m. END OF THIS WORKSHEET GMs Fuel Cell Car BASIC STEAM ENGINE BOILER Shell Longitudinal stress S L Shell Circumferential stress S C Spherical head stress S H PR 2 t Design shell thickness ts MATH TOOLS LINKS Actual Thin Wall Pressure Vessel Stress SPREAD SHEET METHODS. Design of shell under internal pressure.

For design of Pressure Vessel Sandhya consultancy used PV Elite Software and GA for Customer approval purpose as. 1 He 0785varG2Pe end load external pressure 07851212520 0. Presents an overview of the types of vessels under external pressure and materials used for construction Assesses axisymmetric.

P pressure loss inches of water 100 ft of duct where 05 VP 5 P 5 P is an approximation of the loss in the tool 007 P is the entry loss for a flanged cone from the Cincinnati Fan Booklet 05 P is the entry loss for a flanged pipe from the Cincinnati Fan Booklet Click here to see the CFM Requirements Table. Raj Consultancy services have gained immense appreciation with our clients to our clear designing. Pressure Vessel Nozzle with Repad Design Tool per.

Pressure Vessel Nozzle Design Spreadsheet Calculator Design calculations for pressure vessel nozzle per. Up to 24 cash back Tools for Design Estimation of Pressure Vessels and Shell Tube Heat Exchanger. UG-27c12 This sheet will not calculate thick walled vessels Treq 05Do2 Use the Weld Efficiency program to calculate El and Ec.

Grooved Metal Graphite Layer Inside the Bolt Circle k0mm k0KDNmm 20BD KD 0 MPa DIN 2505 k1mm 11BD KDϑ 0 MPa DIN 28090 σVU 0 MPa σVO 0 MPaσBO 0 MPa. Calculations per ASME code include. The book also.

Accessing this resource requires an active Premium Membership with. 2 PD 5500 IS 2825 EN 13445 etc. Design calculations for both internal and external pressure applied on shells.

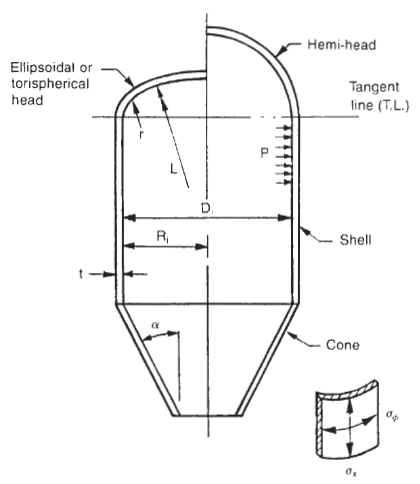

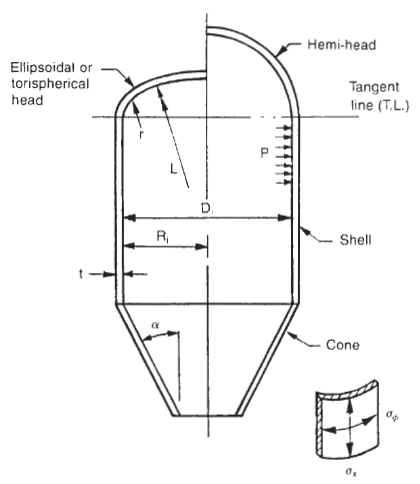

Up to 24 cash back Maximum Allowable Pressure calculation MAXIMUM ALLOWABLE PRESSURE CALCULATION 83031552 150 200 866 150 stress calculation STRESS CALCULATION 438351 10000 90939 785762 200 opening is adequately reinforced opening is not adequately reinforced increase thickness of reinforcing elements. Design of cone under internal and external pressure. 3 HD pi4 B2 P end load PI4 113762 201 20425.

2 HP 2varb314varGmP contact load 20135314121250201 0. Design of dish under internal pressure. Lamination issue in pressure vessel causes matigation REQUEST Spreadsheet for External pressure.

Often vessels are design for some amount of external pressure to allow for steam cleaning and the effects of the condensing steam. MinPint1Pint2 maximum allowed design pressure This sheet cannot be used to check for allowable exterior pressure loads. Pressure Vessel Design Manual is a solutions-focused guide to the many problems and technical.

All software provided As-Is with no warranty expressed or. Pressure Vessel Design Manual Dennis R. - Vessel Supports Spreadsheet As per Pressure Vessel Design Manual-Dennis Moss.

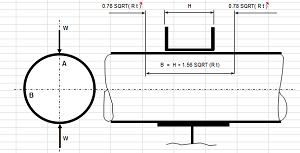

Actually I have to design a long horizontal pressure vessel18000mm where thickness due to internal pressure is coming out to be 7 mm but in case of external pressure it is coming out to be 17 mm for which I need stiffeners. Treq in Treq. THICKNESS OF SHELLS UNDER INTERNAL PRESSURE Cylindrical Shells-Circumferential StressLongi P R Do No Equipment Internal design Inside radius Outside Diameter pressure 1 0 2 3 Circumferential StressLongitudinal Joints t S E t Shell Thickness Maxallowable Joint minumum required Corrosion stress efficiency thickness of shell 085 DIV0.

They have a variety of applications in industry including in oil refineries nuclear reactors vehicle. 11Design Pressure P 04331rhoh 30 04331 0 0mDp 300 12 13Hydro Test UG-99bpressure measured at top of vessel rounded up 14Test Press P 13 MR 30 13 1mTp 39 15 16Material Properties ASME IID 17150. Rectangular Tank Design with Horizontal Stiffening.

The concrete and precise calculation criteria provided can be immediately applied to actual designs. If a 500 inch diameter vessel is 90 filled with a fluid of density 00362lbin³ and an over-pressure of 30psi is applied at the surface of the liquid the maximum pressure at the top of the vessel will be 30psi whilst the maximum pressure at its base will be 4629psi. Process Piping Calculator per ASME B313.

UG-37 Appendix 1-10 1-7 and div 2. Need suggestion on Design of experiments. Engineering Excel Spreadsheet Downloads Welding Design and Engineering Pressure Vessel Design and Engineering.

ALLOWABLE STRESS REFERENCE Calculation Reference API 650 Oil Tank Design Pressure Vessel Design Calculation Preview. Design of Pressure Vessels as per ASME Boiler and Pressure Vessel Code Sec. Other vessels are in vacuum service by.

Download File - Lifting Lug Design Spreadsheet. Basic Pressure Vessel Stressxls. 10 ASME Sec II part D Fig G From Fig G using LDo and Dot From Fig HA-3 for 304L ASME Sec VIII Div 1 Maximum Allowable external working UG-28 Pressure A B Pa 4B3.

The design pressure may be less than atmospheric due to condensing gas or steam. T m a x t c t l t u. PRESSURE VESSEL SHELLS MATERIALS FUEL CELL CARS A fuel cell.

Rajeev383 when you calculate a cylinder to external pressure per ASME VIII there is no such thing as an allowable. For cylindrical shell the thickness t shall be the maximum amongst t c t l and t u ie. Skirt Support Vessel Design.

T c and t l for cylinder and t s p h for sphere. Design of cylindrical shell under external pressure. 4 HDe pi4 B2 Pe end load external pressure PI4 113762 0 0.

Nasrul M Asral namasral Submitted On. Design of dish under external pressure. 4629 90 x 500 x 00362 30.

Calculate the thickness of the shell based on the internal design pressure ie. Branch reinforcement calculation spreadsheet. Cylindrical Shell Internal and External Pressure Vessel Spreadsheet Calculator.

Shell Thickness Calculation Under External Pressure In Pressure Vessels Youtube

Pressure Vessel Thickness Calculation Codecalculation Com 1 Documentation

Hand Calculations Pressure Vessel Engineering

Spreadsheet Calculations Pveng

Pressure Vessel External Pressure Calculations

Pressure Vessel Design Formula And Calculators Resources

0 comments

Post a Comment